河北長鑫和裕有限公司

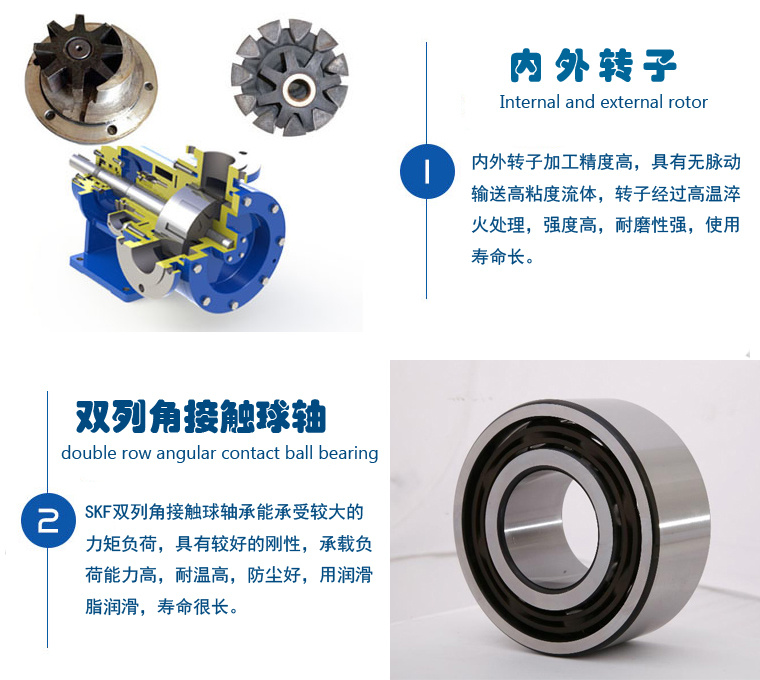

0317-8181885

18830718315

admin@hous.cc

河北(běi)省泊頭市(shì)道東(dōng)街80号

轉子(zǐ)泵填料密封 帕姆(mǔ)泵 nyp110-ru-t1-w11 高粘(zhān)度泵

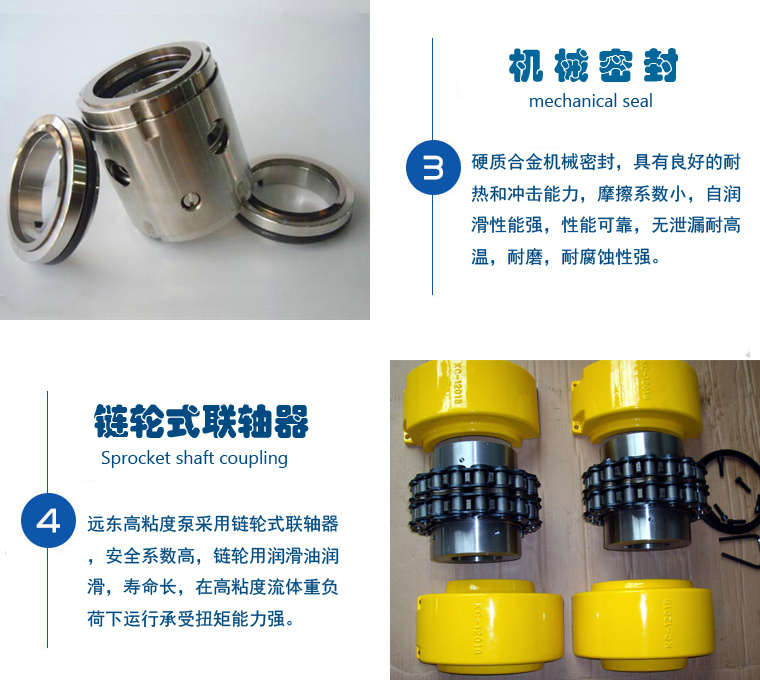

我公司是(shì)一個生産齒輪(lún)油泵(bèng)和螺杆泵(bèng)的專(zhuān)業公司。公司擁有各種設(shè)備80台,主要(yào)設備(bèi)有:c6140 cw6163c車(chē)床24台,tx611c/4镗床(chuáng)2台,m131m7130磨(mó)床8台,c125a立車(chē)2台,y318k y3150e滾齒(chǐ)機6台,e3050x16/1搖(yáo)臂鑽床2台(tái),e5163立式(shì)鑽床2台,b1-400銑床3台(tái),螺杆泵(bèng)轉(zhuǎn)子專(zhuān)用qh2-007銑床(chuáng)1台,半自(zì)動螺(luó)旋轉子qh2-029b銑(xǐ)床2台,x53k立銑3台,半(bàn)自動螺旋(xuán)轉子(zǐ)qh2-031 qh2-032磨刃(rèn)機(jī)台。my company is a company specialized in the production of gear oil pump and screw pump.company has 80 sets of various devices, the main equipment are: c6140 cw6163c 24 sets of lathe, tx611c/boring machine 2 units, 4 m131m7130 grinding machine 8 units, c125a set, 2 sets, y318k y3150e hobbing machine 6 units, e3050x16/1 radial drilling machine 2 sets, e5163 vertical drilling machine 2 sets, b1-400 universal milling machine 3 units, screw pump rotor 1 qh2-007 milling machine, semi-automatic screw rotor qh2-029 - b milling machine 2 sets, x53k three vertical milling, semi-automatic screw rotor qh2 qh2-031-031 edge grinding machine is used.

我公(gōng)司擁(yōng)有省(shěng)計(jì)量局制(zhì)試驗台1台(tái),自制(zhì)試驗台3台,使生(shēng)産産品從原材(cái)料投入到産成(chéng)品(pǐn)出廠實(shí)現了(le)全過程檢測。産(chǎn)品出廠合格率(lǜ)99%,具備較強的綜(zōng)合配套制(zhì)造能(néng)力。理化試驗室(shì)、長度計量室是國家(jiā)計(jì)量确認(rèn)合格單位,使産品從原材(cái)料投(tóu)入到産成品出(chū)廠實現了全過(guò)程檢測(cè)。産(chǎn)品出廠合格(gé)率99%,具備(bèi)較強(qiáng)的綜(zōng)合配套(tào)制(zhì)造能力,公(gōng)司年(nián)可生産各(gè)種泵6000多台。my company has the province system test bench 1 bureau of standard measurement, homemade test-bed 3 units, production of products from raw materials into finished goods factory implements the whole process of detection.product factory qualified rate 99%, have strong ability of comprehensive manufacturing.physical and chemical laboratory, length measuring room is the national metrological confirmation unit, make our products from raw materials into finished goods factory implements the whole process of detection.product factory qualified rate 99%, have strong comprehensive manufacturing capacity, company can produce all kinds of pump in more than 6000 units.

轉(zhuǎn)子(zǐ)泵填料密(mì)封(fēng) 帕姆泵(bèng) nyp110-ru-t1-w11 高粘度泵

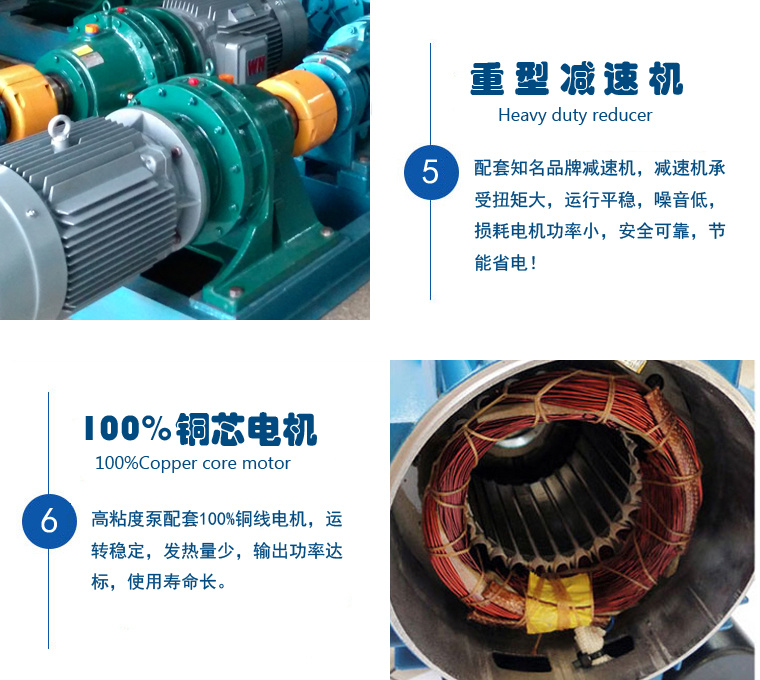

運費說(shuō)明(míng):

1.本(běn)公司常(cháng)規産(chǎn)品(pǐn)1-3天發貨(huò),特殊(shū)要(yào)求或者(zhě)需定做的(de)産品發貨時間(jiān)已與(yǔ)客戶協商為準(zhǔn), 2.泵運(yùn)費方式有兩種:快遞(dì)和物(wù)流.小(xiǎo)泵和小型(xíng)配件(jiàn)發(fā)快(kuài)遞,其(qí)餘體積較大,數量較(jiào)多,推薦走(zǒu)專線物流貨運(yùn),一般南方(fāng),中部(bù)地區及沿海地區3-5天左右(yòu)到達(dá).西部,北部(bù)較遠(yuǎn)的地(dì)區以(yǐ)及少(shǎo)數二次中轉(zhuǎn)地(dì)區5-8天左右(yòu)可到,具體覆蓋範圍(wéi)請咨(zī)詢(xún)公司客(kè)服人員.安裝使(shǐ)用:請您根據(jù)産品說明(míng)書(shū)的步驟進(jìn)行操作,如有問題(tí),請聯系(xì)我公司,為了保(bǎo)護您(nín)的(de)利益,我(wǒ)們已(yǐ)經(jīng)提(tí)醒客戶在(zài)收到貨物(wù)時,要開箱(xiāng)驗貨,如在打開驗貨(huò)時發現(xiàn)貨物(wù)丢(diū)失,損害或者不符,請拒(jù)簽收,您簽收(shōu)就代表已準确無誤(wù)的收(shōu)到後屋,若在簽收貨物之(zhī)後才發現貨物丢失(shī)或者(zhě)不符(fú),如不負(fù)責(zé).客(kè)戶收到(dào)貨後,産品無法安裝或者規格有誤,本公(gōng)司提(tí)供退(tuì)貨或者換貨服務,退貨或者換(huàn)貨(huò)的(de)客戶(hù)請保證貨物的完好(hǎo)無損,并承(chéng)擔往返運(yùn)費.客(kè)戶收到(dào)後(hòu),如果(guǒ)産品存在質量問題,請在收貨(huò)後7天(tiān)内(nèi)聯(lián)系我(wǒ)公司,提供相關(guān)質量(liàng)問題(tí)圖片(piàn),我公司将在(zài)時(shí)間給您退貨或(huò)者換貨,因為我(wǒ)公司已經在發(fā)貨前已經仔細(xì)檢查過,所以過期将不(bú)提供此(cǐ)項服務(wù),還請諒(liàng)解.

●高(gāo)粘度(dù)齒輪泵并(bìng)不能産生壓力(lì),它隻(zhī)是輸(shū)出流量。壓力低(dī)或無壓力(lì),說明高粘(zhān)度齒 輪(lún)泵沒有(yǒu)吸入液體(tǐ)或洩(xiè)漏嚴(yán)重。high viscosity gear pump does not generate pressure, it is only the output flow.pressure is low or no pressure, high viscosity gear wheel pump don't inhale the liquid or leakage is serious.

●高(gāo)粘度(dù)齒輪泵并(bìng)不能産生壓力(lì),它隻(zhī)是輸(shū)出流量。壓力低(dī)或無壓力(lì),說明高粘(zhān)度齒 輪(lún)泵沒有(yǒu)吸入液體(tǐ)或洩(xiè)漏嚴(yán)重。high viscosity gear pump does not generate pressure, it is only the output flow.pressure is low or no pressure, high viscosity gear wheel pump don't inhale the liquid or leakage is serious.

電動機輸出(chū)功率偏小、齒 輪(lún)泵排量(liàng)選得過(guò)大或(huò)壓力調得(dé)過高時,也會造(zào)成壓力不足 當然,壓力表損壞(huài)或壓力(lì)表節流(liú)孔堵塞(sāi)時也(yě)顯(xiǎn)示不(bú)出壓(yā)力,此(cǐ)時可換裝(zhuāng)一個新的(de)壓力表檢(jiǎn)查。small motor output power, gear wheel pump capacity to choose too large or pressure too high, can cause stress pressure gauge damage or pressure gauge orifice jams, of course, also could not show pressure, can change a new pressure gauge to check at this time.

如(rú)果确認泵(bèng)無流(liú)量輸出,可能是由于泵(bèng)安(ān)裝有誤、泵的轉向不對,或吸人側(進(jìn)液口(kǒu)及吸液管(guǎn)道)堵(dǔ)塞、出口止(zhǐ)回閥裝反(fǎn)或卡(kǎ)死了(le),也有可能(néng)是驅動軸斷裂(liè)了。if confirmed that no flow pump output, could be turned to the pumps due to pump installation is wrong, wrong, or suction side (liquid into the mouth and suck liquid pipeline jam, export check valve installed backwards, or card is dead, it is possible that the drive shaft fracture.

高(gāo)粘度(dù)泵在轉速過低時(shí)會(huì)引起(qǐ)出液量(liàng)不(bú)足,這(zhè)種現象往往是(shì)由于泵的驅動(dòng)裝置打滑或功(gōng)率不足(zú)所緻。此(cǐ)時應檢查齒 輪(lún)泵的實際(jì)轉速、泵與(yǔ)電(diàn)動(dòng)機的(de)聯接及功率匹配情況等(děng)。high viscosity pump in low speed can cause insufficient quantity of produced liquid, this phenomenon is often due to the slippage of the pump drive or insufficient power.check the gear wheel pump at this time of the actual speed, pump and motor connection and power matching, etc.

●高粘(zhān)度泵在開(kāi)始運轉前,往齒輪泵(bèng)的殼體内灌滿待(dài)輸(shū)送的(de)液體(tǐ),便于安全(quán)啟動。若環境溫(wēn)度低(dī)于冰點,應(yīng)預先向泵内通(tōng)入熱(rè)蒸汽(qì),進行(háng)預熱處理,然後(hòu)才可(kě)啟(qǐ)動(dòng)齒輪(lún)泵。高(gāo)粘度(dù)泵(bèng)的(de)旋轉方向要與(yǔ)進、出油口相符(fú)。齒輪(lún)泵若是次(cì)運行(háng),或長(zhǎng)期閑(xián)置後(hòu)再(zài)使用(yòng),在(zài)空載或小(xiǎo)負荷(hé)情況(kuàng)下先(xiān)跑合(hé)一小時左右。如果在跑合階段(duàn)預先覺察出異常溫升、洩(xiè)漏、振動和噪(zào)聲時,應停機(jī)檢查。高粘(zhān)度(dù)齒輪泵(bèng)的支(zhī)座或(huò)法蘭與其(qí)驅動(dòng)電機(jī)應采用共(gòng)同的(de)安裝基礎,基礎、法蘭或支座(zuò)均需具(jù)有足夠(gòu)的(de)剛度(dù),以減(jiǎn)小(xiǎo)齒輪泵(bèng)運轉時(shí)産生的(de)振動(dòng)和噪(zào)聲。電(diàn)動(dòng)機(jī)與齒(chǐ)輪泵(bèng)須用(yòng)彈性(xìng)聯(lián)軸器連(lián)接,同(tóng)軸度小于0.1毫(háo)米,傾斜(xié)角不得大于1度(dù)。安裝聯(lián)軸(zhóu)器時(shí)不得用錘敲打,以免傷害(hài)齒輪(lún)泵的齒(chǐ)輪(lún)等零(líng)件。若用(yòng)帶輪、鍊(liàn)輪等驅(qū)動(dòng)時應(yīng)設托架支承(chéng),以(yǐ)防主動(dòng)齒輪軸(zhóu)承受徑向力。緊固齒輪泵(bèng)、電動(dòng)機的(de)地腳螺釘(dìng)時,螺釘受力應(yīng)均勻,連接可靠(kào)。用手轉(zhuǎn)動(dòng)聯軸(zhóu)器時,應感覺到(dào)齒(chǐ)輪泵(bèng)能夠輕(qīng)松地轉動,沒有(yǒu)卡緊等異(yì)常現象出現(xiàn),然(rán)後才(cái)可以配管(guǎn)。

丁苯乳膠(jiāo)輸送泵用nyp110-ru-t1-w11配減(jiǎn)速機泵裝機械(xiè)密封

高粘(zhān)度齒輪泵(bèng)的吸油管道内(nèi)徑應足夠大,并(bìng)避免狹窄(zhǎi)通道(dào)或急劇拐彎、減(jiǎn)少彎(wān)頭,去除不(bú)必要(yào)的閥(fá)門、附(fù)件,盡可能(néng)地降(jiàng)低泵的安裝高度,縮短吸(xī)油管(guǎn)道的長度(dù),以減(jiǎn)少壓力損失。管(guǎn)接頭(tóu)等(děng)元(yuán)件的(de)密封要良好,以(yǐ)防止(zhǐ)空氣侵入(rù),從而控制(zhì)氣穴(xué)與氣蝕的發生(shēng)。止回閥與安全閥在(zài)齒輪泵的(de)輸出管(guǎn)路上安(ān)裝一(yī)個止回閥(fá)。這(zhè)樣(yàng)在檢(jiǎn)修泵(bèng)及輸出管道時(shí),系統中的(de)液體(tǐ)不會發生倒流(liú)。齒輪泵帶(dài)負荷停車時,亦(yì)可防(fáng)止泵倒轉而在(zài)其輸(shū)出管道内(nèi)産生局部真空(kōng)。應當(dāng)注意(yì),出口止回閥不能裝反或出現卡死(sǐ)現象(xiàng)。高(gāo)粘度泵(bèng)的出口(kǒu)管路上(shàng)還應當設置安(ān)全閥(fá)等保護裝(zhuāng)置,這樣一旦泵的出口通(tōng)道發(fā)生堵塞(sāi),就(jiù)可以(yǐ)打開(kāi)安(ān)全閥卸(xiè)壓。安全(quán)閥可以與泵體(tǐ)或泵蓋鑄成一體(tǐ),也可(kě)以單(dān)獨(dú)裝(zhuāng)配。對于需要正反轉(zhuǎn)的高粘度齒輪(lún)泵,其進出(chū)口管(guǎn)路上(shàng)均需設置(zhì)安全閥。 高粘度(dù)泵是輸送高粘(zhān)度液體的(de)齒輪(lún)泵,應做到在較(jiào)低的功耗(hào)、較少的洩漏、較大的(de)壓力(lì)下(xià)輸出多(duō)的流量。在确定(dìng)所要(yào)輸送的介(jiè)質時(shí),應該嚴格(gé)遵循産(chǎn)品說明(míng)書上(shàng)的規定,盡(jìn)量使用廠家推(tuī)薦的(de)流體介質(zhì),并注意考(kǎo)慮系(xì)統的工(gōng)作溫度(dù)範圍(wéi)。當希望在(zài)某一較寬的溫(wēn)度範圍(wéi)内使用時,輸送(sòng)介質的(de)粘度(dù)指數應該高些(xiē)。輸送介質(zhì)不(bú)僅是能量傳(chuán)遞的(de)中介,而且(qiě)也是潤滑(huá)、密封(fēng)及傳熱介(jiè)質。液(yè)體粘(zhān)度過高會增加(jiā)内摩擦阻(zǔ)力,降低(dī)輸(shū)出功(gōng)率,浪費能(néng)量,并(bìng)産生過高的系(xì)統溫度.高粘度齒輪泵(bèng)的(de)出口(kǒu)管路上應當設(shè)置安全閥(fá)等保護裝(zhuāng)置,這樣一(yī)旦泵的出口通道發(fā)生堵塞,就(jiù)可以打開安全閥卸(xiè)壓。對于需(xū)要正反轉(zhuǎn)的高粘度(dù)齒(chǐ)輪泵,其(qí)進出口(kǒu)管(guǎn)路上(shàng)均需設置安全(quán)閥。high viscosity pump is conveying liquid with high viscosity gear pump, should be in lower power consumption, less leakage, under the pressure of large output the most traffic.when determining to conveying medium, we should strictly follow the provisions of the product manuals on use manufacturers recommend fluid as far as possible, and pay attention to consider the system operating temperature range.when you want to use in a wide temperature range, medium viscosity index should be higher.medium is not only the energy transfer intermediary, but also lubrication, sealing and heat transfer medium.liquid viscosity is too high will increase internal friction resistance, lower output power, waste of energy, and generate high temperature system. high viscosity gear pump outlet pipe shall set up relief valve or other protective device on the road, so once the clogging pump export channels, can open the relief valve pressure relief.for high viscosity gear pump need positive &negative, import and export all needs to set up the line safety valve.

1、工(gōng)作壓力的選定(dìng)1, select the work pressure

高粘度(dù)泵額定(dìng)的壓(yā)力是指泵(bèng)連續(xù)工作(zuò)時的(de)高許(xǔ)用壓力(lì),而其工(gōng)作壓(yā)力(lì)則決定(dìng)于外部負載,安(ān)裝和(hé)調試的壽(shòu)命與(yǔ)其工(gōng)作壓(yā)力直(zhí)接(jiē)相關。對(duì)于不(bú)頻繁(fán)工作(zuò)的齒輪泵,其工(gōng)作壓(yā)力可取為泵的額定壓力(lì),考慮到(dào)産(chǎn)品質量不(bú)同(tóng),将額定(dìng)壓力降(jiàng)低20%~30%使用(yòng)。對于(yú)經常工作于較高壓力下的齒輪(lún)泵,其工作壓(yā)力(lì)應比泵的額(é)定壓力低(dī)1~2個壓力級。石油(yóu)化工設備(bèi)常常(cháng)是24小時(shí)連續運轉,這時泵的工(gōng)作壓(yā)力應該取(qǔ)得比額定壓力(lì)低得多(duō),且工作(zuò)轉速(sù)也應該低(dī)于額定轉速。如果高粘度齒輪(lún)泵的工作壓力調整(zhěng)過高,則會(huì)使齒輪(lún)泵(bèng)在超(chāo)負荷下運行。high viscosity pump rated pressure refers to the maximum allowable pump continuous work pressure, and its working pressure is determined by the external load, installation and commissioning of life is directly related with work pressure.for not frequent work gear pump, the working pressure is desirable for the rated pressure of the pump, taking the quality into consideration, it is best to used pressure rated lower 20% ~ 30%.for often work under high pressure gear pump, the working pressure shall be lower than the rated pressure of the pump 1 ~ 2 pressure level.petrochemical equipment are often 24 hours of continuous operation, and at this time of the pump working pressure should be obtained was much lower than the rated pressure, and the work speed should be lower than the rated speed.if the high viscosity gear pump high pressure adjustment, will make the pump running under overload.

2.安裝與(yǔ)試運轉2. installation and commissioning

高粘度(dù)泵的(de)支座(zuò)或法蘭與(yǔ)其驅(qū)動電(diàn)機應(yīng)采(cǎi)用(yòng)共同的安(ān)裝基礎(chǔ),基礎、法蘭或(huò)支座(zuò)均需(xū)具有足(zú)夠(gòu)的剛(gāng)度,以(yǐ)減小齒輪(lún)泵(bèng)運(yùn)轉時産生(shēng)的振動(dòng)和(hé)噪聲。電動(dòng)機與(yǔ)齒輪泵須用彈性聯(lián)軸器連接(jiē),同軸(zhóu)度小于(yú)0.1毫米,傾(qīng)斜角不得(dé)大(dà)于(yú)1度。安裝聯軸器(qì)時不得用錘敲打,以免傷(shāng)害齒(chǐ)輪泵(bèng)的齒輪等零件(jiàn)。若用帶輪、鍊輪等驅動時(shí)應設(shè)托架支承(chéng),以防主動(dòng)齒輪軸承受徑向力(lì)。緊固齒(chǐ)輪(lún)泵、電(diàn)動機(jī)的地(dì)腳螺(luó)釘時,螺釘受力(lì)應均勻,連接可靠。用手轉動聯(lián)軸器(qì)時,應感覺(jiào)到齒輪泵(bèng)能夠(gòu)輕松地轉動,沒有卡(kǎ)緊等(děng)異常現(xiàn)象(xiàng)出(chū)現,然後(hòu)才可以配管。高(gāo)粘度(dù)齒輪泵的(de)吸油管道内徑應足(zú)夠(gòu)大(dà),并避(bì)免(miǎn)狹窄通道或(huò)急劇(jù)拐(guǎi)彎、彎頭(tóu),去除不(bú)必要的閥門、附件,盡可(kě)能地(dì)降(jiàng)低泵的(de)安裝高(gāo)度,縮短(duǎn)吸油(yóu)管道的(de)長(zhǎng)度,以減少(shǎo)壓力(lì)損失。管(guǎn)接頭等(děng)元件(jiàn)的密封要良好,以防止空(kōng)氣侵入(rù),從而控(kòng)制氣穴與氣蝕的發生。在(zài)開始(shǐ)運轉前,往(wǎng)齒輪泵的殼(ké)體内灌(guàn)滿待(dài)輸送的液體,便(biàn)于安(ān)全動(dòng)。若環境溫(wēn)度低(dī)于冰(bīng)點,應預先(xiān)向(xiàng)泵内(nèi)通入熱蒸汽,進行預(yù)熱處理,然後(hòu)才可(kě)啟動齒輪泵。齒輪泵(bèng)的旋轉方(fāng)向要(yào)與進、出油(yóu)口相符。齒輪泵(bèng)若是次運行,或(huò)長期閑(xián)置(zhì)後再使用,在空載或(huò)小負荷情況下(xià)先跑合(hé)一小(xiǎo)時左右(yòu)。如果在跑(pǎo)合階段預先覺(jiào)出異常(cháng)溫升、洩(xiè)漏、振動和噪聲(shēng)時,應(yīng)機檢(jiǎn)查(chá)。高(gāo)粘度泵的出口管路上(shàng)還(hái)應當(dāng)設置(zhì)安全閥等(děng)保(bǎo)護裝置,這樣(yàng)一旦泵(bèng)的出口(kǒu)通道發生(shēng)堵塞(sāi),就可以打開安(ān)全閥卸壓(yā)。對于(yú)需要正(zhèng)反轉的(de)高粘度齒(chǐ)輪泵,其進出口(kǒu)管路(lù)上均需(xū)設(shè)置安(ān)全閥。

2.安裝(zhuāng)與試(shì)運轉2. installation and commissioning

高粘(zhān)度泵(bèng)的支座或法蘭與其(qí)驅動電機應采(cǎi)用共同(tóng)的(de)安裝基礎,基(jī)礎(chǔ)、法蘭(lán)或支座均(jun1)需具有足夠的剛度,以減小齒輪泵(bèng)運轉(zhuǎn)時(shí)産(chǎn)生的振動和噪聲。電(diàn)動機與齒輪泵須用彈性聯軸(zhóu)器連接,同軸度(dù)小于0.1毫(háo)米,傾斜角不得大(dà)于1度(dù)。安裝聯軸(zhóu)器時不得(dé)用錘敲打,以(yǐ)免傷害齒輪(lún)泵的(de)齒輪等零(líng)件。若(ruò)用帶輪、鍊輪等驅動時應(yīng)設托(tuō)架支承,以(yǐ)防主動齒輪軸(zhóu)承受徑向力(lì)。緊固齒輪泵(bèng)、電動(dòng)機的地(dì)腳螺釘時,螺釘受力應(yīng)均(jun1)勻(yún),連(lián)接可靠(kào)。用手轉動(dòng)聯(lián)軸(zhóu)器時,應感覺到齒輪(lún)泵能(néng)夠輕松地轉動(dòng),沒有(yǒu)卡緊等(děng)異常現(xiàn)象出現,然(rán)後(hòu)才可以(yǐ)配管。高粘(zhān)度齒輪(lún)泵的吸油管(guǎn)道内徑應(yīng)足夠大,并避免狹窄(zhǎi)通道或(huò)急(jí)劇拐彎(wān)、減(jiǎn)少彎(wān)頭,去(qù)除不必要(yào)的閥門、附件,盡(jìn)可能地(dì)降(jiàng)低泵(bèng)的安裝高(gāo)度,縮(suō)短吸(xī)油管(guǎn)道的(de)長度,以減(jiǎn)少壓(yā)力損(sǔn)失。管(guǎn)接頭(tóu)等元件的(de)密封要良(liáng)好,以防止(zhǐ)空氣侵入(rù),從而控制氣穴與氣(qì)蝕的發生。在開始運轉前,往齒(chǐ)輪泵的殼體(tǐ)内(nèi)灌滿待(dài)輸(shū)送的(de)液體,便于安全啟動。若環境溫(wēn)度(dù)低于冰點,應(yīng)預先(xiān)向泵(bèng)内通(tōng)入熱蒸汽(qì),進行預熱(rè)處(chù)理,然後(hòu)才可(kě)啟動齒輪(lún)泵。齒輪泵(bèng)的旋(xuán)轉方向要(yào)與(yǔ)進、出油口相(xiàng)符。齒(chǐ)輪泵(bèng)若是(shì)次運(yùn)行,或長期閑置(zhì)後(hòu)再(zài)使(shǐ)用,在空(kōng)載或小負荷情(qíng)況下先跑(pǎo)合一(yī)小時左(zuǒ)右。如果(guǒ)在跑合階段預先覺察出異常(cháng)溫升、洩漏、振動和噪(zào)聲時(shí),應機(jī)檢查。high viscosity pump bearing or flange and its drive motor should use common installation basis, foundation, flange or support all needs to have enough rigidity, to reduce the vibration of gear pump is running and noise. motor and gear pump with elastic shaft coupling, coaxial degree is less than 0.1 mm, angle shall not be greater than 1 degree. when installing coupling hammer shall not be used, in order to avoid damage gear and other parts of the gear pump. if use the belt wheel, wheel, etc, shall set bracket support, in case of driving gear bearing by the radial force. ground screw fastening gear pump, motor, screw force should be uniform, reliable connection. turn the coupling with the hand, should feel can easily turn the gear pump, no abnormal phenomenon such as clamping, then can be piping. high viscosity gear pump oil suction pipe diameter should be large enough, and to avoid the narrow channel, or a sharp turn, reducing elbow, remove unnecessary valves, fittings, as much as possible to reduce the installation height of pump, shorten the length of the oil suction pipe, in order to reduce the pressure loss. components, such as pipe joint sealed well, in order to prevent the air intrusion, thus control air-pocket and the occurrence of cavitation. before starting operation, to gear pump casing filled with liquid, facilitate safe launch. if the environment temperature is below freezing, should advance to pump into the hot steam, preheating treatment, and then to start the pump. direction of rotation of the gear pump, oil outlet in accord. gear pump is the first run, or long-term idle before using, had better under the condition of no load or small load to run one hour or so. if in the running-in stage in advance detect abnormal temperature rise, leakage, vibration and noise, should machine inspection.

高粘(zhān)度(dù)泵的出口管(guǎn)路上(shàng)還應當設(shè)置安(ān)全(quán)閥(fá)等保護裝(zhuāng)置(zhì),這樣一(yī)旦泵(bèng)的出(chū)口通道(dào)發生(shēng)堵塞,就(jiù)可以打開安全(quán)閥卸壓。對于需(xū)要正(zhèng)反(fǎn)轉的高(gāo)粘度(dù)齒輪泵,其(qí)進出口管(guǎn)路上(shàng)均需(xū)設置安全(quán)閥。high viscosity of the pump outlet pipe also shall set up relief valve or other protective device on the road, so that once the clogging pump export channels, can open the relief valve pressure relief. for high viscosity gear pump need positive &negative, import and export all needs to set up the line safety valve.

轉(zhuǎn)子泵(bèng)填料(liào)密封(fēng) 帕姆(mǔ)泵 nyp110-ru-t1-w11 高(gāo)粘度(dù)泵(bèng)

●輸(shū)送介質的(de)優(yōu)勢(shì):the advantage of the medium:

高粘(zhān)度泵(bèng)可以(yǐ)輸送(sòng)高粘(zhān)度、高濃度(dù)無固體顆粒或(huò)細小軟(ruǎn)顆(kē)粒的(de)潤滑性介質;效率高,性(xìng)能穩定(dìng),使用壽命(mìng)長。高(gāo)粘度(dù)泵可以采(cǎi)用保(bǎo)溫夾(jiá)套結(jié)構,輸送比較高(gāo)的粘度物料時可以(yǐ)對高粘度(dù)泵進行保(bǎo)溫,從(cóng)而降低介質粘(zhān)度,達到更(gèng)好的(de)輸送效果,而單(dān)螺杆(gǎn)泵沒有保(bǎo)溫夾套(tào)結構;高(gāo)粘度泵在(zài)使用(yòng)一段時間(jiān)後,如(rú)果泵内部(bù)間隙(xì)磨損後,不用拆(chāi)泵(bèng)可(kě)以自行根據高粘度泵所(suǒ)輸送(sòng)的物料粘(zhān)度來調整泵的(de)間隙(xì),調(diào)整後和(hé)新泵(bèng)一樣可以(yǐ)達到良好(hǎo)的使用效果。高粘度(dù)泵可配(pèi)安全閥,當泵或(huò)管路系統超壓時,安全(quán)閥門打(dǎ)開,形(xíng)成内部回流(liú),保證系統(tǒng)安全(quán)。而單(dān)螺杆(gǎn)泵在(zài)泵本身不能設置安(ān)全閥(fá),隻(zhī)能在(zài)管(guǎn)路中設置,提高(gāo)了設(shè)備投(tóu)入成(chéng)本和安裝成本(běn)。選擇高粘度泵時必須考慮高(gāo)粘度泵(bèng)所(suǒ)輸送的介(jiè)質粘(zhān)度,從(cóng)而才能來确定(dìng)高粘度泵(bèng)的轉(zhuǎn)速範圍,根(gēn)據高(gāo)粘度泵的轉速(sù)範圍及所需工況條件(jiàn)下(xià)高粘(zhān)度泵(bèng)的正常流(liú)量範圍,才能确(què)定高粘度泵具體型号(hào)。需要注(zhù)意的是(shì)一般介(jiè)質可以這樣來(lái)選擇。high viscosity pump can transport high viscosity, high concentration without solid particles or small soft particles lubricity medium; high efficiency, stable performance and long service life. high viscosity pump can be used in a heat preservation jacket structure, transmission is higher when the viscosity of the material can be for thermal insulation in high viscosity pump, thereby reducing medium viscosity, achieve better transmission effect, and the single screw pump heat preservation jacket structure; high viscosity pump in use after a period of time, if the pump internal clearance after wear, don't have to dismantle the pump to according to the viscosity of material delivery by high viscosity pump to adjust the clearance between the pump and adjusted, and the use of the new pump can achieve good effect. high viscosity pump can match the relief valve, when the pump and piping system overpressure, safety valve is opened, the formation of internal reflux, ensure the safety of the system. and single screw pump in the pump itself cannot set the relief valve, can only be set up in line, increase the investment of equipment cost and installation cost. choosing high viscosity pump must consider the conveying medium viscosity, high viscosity pump order to determine the scope of the high viscosity of the pump rotation speed, according to the working condition of high viscosity of the pump speed range and required high viscosity pump under the condition of normal flow range, to determine the high viscosity pump concrete models. it's important to note that it can be to choose a normal medium.

其中,有些(xiē)特殊(shū)化學介質在一(yī)定溫(wēn)度下會改(gǎi)變其化(huà)學成分(fèn),所以(yǐ)需要在(zài)選(xuǎn)擇高(gāo)粘度泵要(yào)特别注意(yì)泵的轉速是否(fǒu)适合,因為泵的轉速(sù)越高,正(zhèng)常(cháng)工作(zuò)中産生(shēng)的(de)熱量就越(yuè)大(dà),一旦超過介質所限制(zhì)的溫度,那麼就多所輸(shū)送的介質造(zào)成了(le)破壞(huài)。還有些(xiē)食(shí)品類(lèi)介質,比如果醬(jiàng)類,像(xiàng)我們日常(cháng)中所食用(yòng)的果(guǒ)醬、花生醬(jiàng)、豆瓣(bàn)醬等,這(zhè)些(xiē)介質(zhì)要求(qiú)在輸送過(guò)程中必(bì)須(xū)不能(néng)夠破(pò)壞其内(nèi)部(bù)的成分進行破(pò)壞,這就要求我(wǒ)們所選的(de)泵的轉速必須要低(dī),才能(néng)保(bǎo)證高粘(zhān)度泵在輸送過(guò)程中不(bú)破壞所(suǒ)輸送(sòng)的介質。高粘度泵在(zài)運轉(zhuǎn)過程(chéng)中常常會(huì)出現卡死(sǐ)、抱軸(zhóu)轉不(bú)動(dòng)的現象(xiàng),主要(yào)原因(yīn)是高粘度(dù)泵往往都(dōu)是輸(shū)送的高(gāo)粘(zhān)度的介質(zhì),有些(xiē)是有一些雜質的混(hùn)合物理。如果(guǒ)泵(bèng)的入口沒(méi)有安裝合适(shì)的過濾器,那(nà)麼一(yī)旦大(dà)一(yī)些的硬質顆(kē)粒進入泵腔就(jiù)會把高粘(zhān)度泵的内(nèi)外轉子卡(kǎ)死(sǐ),使泵轉(zhuǎn)不動(dòng),嚴(yán)重的會把高(gāo)粘度(dù)泵的(de)内(nèi)外(wài)轉子(zǐ)毀掉(diào)。

所以(yǐ)建議(yì)大家(jiā)在安裝高(gāo)粘(zhān)度泵的(de)時候應該選擇合适的過濾器(qì)來安裝在泵的(de)入口。高粘度泵(bèng)抱軸(zhóu)的現象主(zhǔ)要體(tǐ)現在不鏽(xiù)鋼高粘度(dù)泵的(de)較多(duō),因為不(bú)鏽(xiù)鋼材質含碳量(liàng)低,所以熱膨脹系數(shù)大(dà),一(yī)旦泵的溫度(dù)過高,就(jiù)會造成泵(bèng)的内(nèi)部配件與配件(jiàn)之間的(de)間(jiān)隙縮小,到(dào)一(yī)定程度以後就會(huì)産生(shēng)抱死現象。所以(yǐ)選擇不鏽(xiù)鋼材質的(de)高粘度泵是一(yī)定要注明(míng)具體(tǐ)的使用溫(wēn)度,及介質的潤滑性。介質(zhì)粘度(dù)的高低(dī)與高粘(zhān)度泵的轉速有着密不(bú)可(kě)分的(de)關系(xì)。如(rú)果(guǒ)高粘度泵輸送(sòng)的介(jiè)質粘度過(guò)高,而(ér)所配(pèi)的轉(zhuǎn)速也(yě)過高的話,就會(huì)造成泵的(de)流量(liàng)很低(dī)、泵的噪音(yīn)很大(dà)。如果電機(jī)功率還是按常(cháng)規來配(pèi)的話,那(nà)麼電(diàn)機也會造(zào)成過載。主(zhǔ)要是(shì)泵的轉速太高(gāo)、介質(zhì)粘度又太高這(zhè)樣(yàng)就會造(zào)成泵(bèng)阻力很(hěn)大,電機(jī)的瞬間啟(qǐ)動電(diàn)流超過額定電流(liú),造(zào)成電機(jī)過(guò)載;由于轉(zhuǎn)速過高,使高(gāo)粘(zhān)度泵(bèng)在運(yùn)轉時(shí)内部轉子(zǐ)幾乎(hū)隻是形(xíng)成了空(kōng)轉,圍繞(rào)所輸送(sòng)介質打滑(huá),造成(chéng)吸不上(shàng)料,或者(zhě)是流量(liàng)很(hěn)小。在這種(zhǒng)狀況下,必須降低泵的轉(zhuǎn)速,加大電機的(de)功率,加大進出口的管(guǎn)徑來減少介(jiè)質的流動阻力。從(cóng)而來完(wán)成介質(zhì)的輸送(sòng)工作(zuò)。轉速(sù)降低(dī)以後,泵的(de)流量會反而增加,而且泵的(de)噪音會降低(dī),但肯定打(dǎ)不到理論(lùn)流量。所以(yǐ)如果(guǒ)與實(shí)際工況需要流量相差太多的(de)話,那就(jiù)隻能更好型号更(gèng)大一(yī)點的泵(bèng)。

高(gāo)粘度泵容(róng)易出現(xiàn)的另一(yī)個問題就是(shì)從(cóng)動齒輪的(de)銷軸(zhóu)容易磨損,特别(bié)是對于輸送沒(méi)有潤滑(huá)性的介(jiè)質時,銷軸(zhóu)磨損(sǔn)特别快。對此我公司(sī)改進加工工藝(yì)在原有的(de)基(jī)礎(chǔ)之上通過(guò)特殊(shū)設計改進(jìn)給銷軸配(pèi)套加(jiā)了一套(tào)注(zhù)油潤滑系(xì)統。在(zài)高粘度泵正常運轉(zhuǎn)的情況下通過内轉(zhuǎn)子的旋轉産生的離心力形成的(de)負壓,利(lì)用(yòng)注(zhù)油系統通(tōng)過特殊(shū)通道給(gěi)銷軸注油,從而解決了高粘度(dù)泵銷(xiāo)軸(zhóu)磨(mó)損快(kuài)的這一泵行業(yè)中存在的(de)難題(tí)。another problem of the high viscosity pump is driven gear pin easy to wear and tear, especially for conveying without lubrication medium, pin shaft wear particularly fast. i improved processing technology on the basis of the original company through special design improvements to pin shaft supporting a grease lubrication system. under the condition of the high viscosity of the normal operation of pump centrifugal force produced by the rotation of the rotor within the formation of the negative pressure, the use of injection system through the special channel to pin shaft oil, so as to solve the high viscosity pump pin shaft quick wear of the problems that exist in the pump industry.

●起動前要檢查下(xià)列内容(róng):

1.檢查(chá)泵、齒(chǐ)輪箱和電(diàn)機的對中(zhōng)程度(dù);

2.檢查(chá)過濾(lǜ)器中(zhōng)有沒(méi)有焊皮(pí)和金屬(shǔ)渣;

3.檢查各(gè)連接(jiē)部位(wèi)連接是否緊固;

4.檢查(chá)管(guǎn)路(lù)壓在泵上(shàng)的力(lì)和力(lì)矩(jǔ)是(shì)否超(chāo)過給(gěi)定的數值,如果溫度較高,還(hái)應(yīng)檢查(chá)管路是否有膨(péng)脹節(jiē);

5.檢查電氣連接的正确(què)性(xìng)及電機的(de)額(é)定值,并(bìng)檢查電(diàn)機(jī)轉動(dòng)方向(xiàng)是否正(zhèng)确(què);

6.檢查泵的轉(zhuǎn)動方向(xiàng)是否(fǒu)正(zhèng)确(què);

7.如有(yǒu)安全(quán)閥,安(ān)全閥安裝必須(xū)正确(què),

8.檢查(chá)泵軸(zhóu)是否轉動靈活(huó);

9.泵的内部(bù)不能是幹的,特别(bié)是需要(yào)自吸(xī)的時候,應(yīng)向泵(bèng)内灌注一(yī)些(xiē)油(yóu)或輸送的(de)液體;

10.泵組裝時(shí)在零(líng)件的表面有防護液,如果這種(zhǒng)液體不能(néng)和泵(bèng)送液(yè)體相容(róng),則(zé)必須清(qīng)洗(xǐ);

11.在(zài)管路上(shàng)安裝壓力表和(hé)真空(kōng)表,方便觀(guān)察泵(bèng)的工(gōng)作狀(zhuàng)态;

12.檢(jiǎn)查機械密(mì)封箱是否注滿液體(tǐ);

13.檢查(chá)管路的閥門(mén)是(shì)否打(dǎ)開(kāi);

14.如(rú)果(guǒ)用内燃(rán)機驅(qū)動,請在起(qǐ)動(dòng)發(fā)動機前保(bǎo)持離合(hé)器(qì)脫開(kāi);

泵起(qǐ)動後,檢(jiǎn)查(chá)液體(tǐ)是否進入到泵(bèng)中(zhōng),泵是否工作(zuò)正常,如果長時(shí)間無液體進入泵中(zhōng),應(yīng)停機檢(jiǎn)查泵及管路。

河北遠(yuǎn)東泵業制造有限公(gōng)司售(shòu)後服(fú)務承諾書(shū)

遠東泵業本着(zhe)“高質量、優(yōu)服務(wù)、求發展(zhǎn)”的(de)精神,以“優質産品、合(hé)理價格、貼(tiē)心服(fú)務(wù)”的(de)理念和負(fù)責、公開的原則(zé)向您鄭重承諾:

一、 本(běn)《售後(hòu)服(fú)務承諾書》(以下(xià)簡稱承諾書(shū))作(zuò)為河北(běi)遠東泵業(yè)有限(xiàn)公司(sī)(以下簡稱遠東泵業)所售産品(pǐn)合同的标(biāo)準附件,描述産(chǎn)品質量(liàng)要求、技(jì)術标準(zhǔn)、遠東泵業對質量負責的條件(jiàn)和期限(xiàn)。

二(èr)、 本承諾書承(chéng)諾範圍為經遠東泵業及授權(quán)代理(lǐ)人銷(xiāo)售的工業(yè)産品,以及(jí)相應的售(shòu)後(hòu)服務。

三(sān)、 需方(fāng)在到貨(huò)的一周(zhōu)内對産品進行(háng)驗收,并(bìng)作(zuò)出“驗(yàn)收合格(gé),按合同(tóng)付款(kuǎn)”及(jí)其他意(yì)見。

四、 需方驗收(shōu)的标(biāo)準為産(chǎn)品(pǐn)本身(shēn)已有的國(guó)家标(biāo)準、行業标準、說明書載明(míng)指标(biāo)及其他經供需(xū)雙方(fāng)約定的特殊要求(qiú)。

五、 所(suǒ)有外協(xié)配套産品(pǐn)(如配(pèi)套電(diàn)機、閥門、電(diàn)器等)執行(háng)原(yuán)始生産(chǎn)商的“三包(bāo)”政策,保障(zhàng)需方權益(yì)。

六、 産(chǎn)品配(pèi)發檢(jiǎn)驗合格(gé)證書和(hé)使用說明(míng)書,以(yǐ)确保用戶能正(zhèng)确安(ān)裝使(shǐ)用我公司産品。請需(xū)方在産品(pǐn)說明(míng)書及其他安全(quán)使用指示(shì)下設(shè)計、安裝、使用和(hé)維護産(chǎn)品,并有(yǒu)義務(wù)培(péi)訓産品(pǐn)的其他使(shǐ)用者知悉(xī)這(zhè)些信息(xī)。

七、 我公(gōng)司保證(zhèng)出廠(chǎng)的産品均(jun1)按有關國(guó)家标(biāo)準生(shēng)産和檢驗,不合(hé)格的(de)産品決不出廠。保證嚴格(gé)履行(háng)、兌現(xiàn)産(chǎn)品(pǐn)三包,嚴(yán)格執行國家(jiā)工(gōng)業産品(pǐn)售後服務(wù)有關(guān)規(guī)定(dìng),對出廠産(chǎn)品自發貨日(rì)起的18個(gè)月内或産(chǎn)品安裝12個(gè)月以(yǐ)内(以(yǐ)先到者為(wéi)限),若買方能夠(gòu)證實(shí)産(chǎn)品是符(fú)合本公司(sī)建議(yì)的方(fāng)法正确安(ān)裝與使用;能夠(gòu)證實産品本身(shēn)确有(yǒu)設(shè)計、材料或加工缺陷,并(bìng)向本公(gōng)司提出(chū)書面(miàn)申(shēn)請,本公(gōng)司(sī)将(jiāng)負現(xiàn)缺陷(xiàn)産品(pǐn)現場(chǎng)檢修(xiū)、免費召回維修(xiū)、更換(huàn)或(huò)按(àn)訂貨(huò)價。

八(bā)、 用戶對我(wǒ)公司(sī)産品提(tí)出質量(liàng)異議,公司保證(zhèng)在接到用戶提(tí)出異議後24小時(shí)内作(zuò)出處理意見。若需(xū)現場解(jiě)決的,保證派出(chū)專業技(jì)術服務(wù)人員,并(bìng)做到質量問(wèn)題不解決(jué)服務(wù)人員不撤離。對(duì)每(měi)件用戶反饋的産品質量問(wèn)題及處理(lǐ)結果我公司将(jiāng)予以存檔。

九、 在(zài)任何情形下,本公司(sī)均不承擔(dān)因缺(quē)陷産(chǎn)品維修、更(gèng)換而導緻的勞務、材料(liào)、設(shè)備、工(gōng)程或其他相關(guān)的連帶(dài)費用。本(běn)公司此項産品(pǐn)售後服務承諾可以(yǐ)代替(tì)其他明示(shì)或暗示形式産(chǎn)品質(zhì)量,并(bìng)且(qiě)可視為買方(fāng)的賠(péi)償和(hé)賣方(fāng)的責任。

十、 河(hé)北(běi)遠東(dōng)泵業有限公司(sī)為産品(pǐn)提供終身技(jì)術咨詢及(jí)配件供(gòng)應(yīng)。

我公司(sī)與(yǔ)泊頭其他(tā)泵廠相比(bǐ)存在(zài)的優勢

丁苯乳(rǔ)膠輸(shū)送(sòng)泵(bèng)用nyp110-ru-t1-w11轉子泵配減速機泵(bèng)裝機械密封(fēng)-泊遠東

1、研發(fā)的優勢

公司(sī)共有研發人員(yuán)45人(rén),其中:學術帶(dài)頭人(rén)3人(rén),高級工(gōng)程師9人,工(gōng)程師(shī)21人,初級(jí)技術人員12人。研發人員以(yǐ)碩士、本科為主,其中:碩士6人(rén),本科25人(rén)。

公司具有一(yī)批掌(zhǎng)握(wò)多種容積(jī)泵和(hé)離(lí)心泵(bèng)關鍵技術(shù)和制(zhì)造工藝(yì)的(de)專業(yè)技術(shù)人(rén)才(cái),具有(yǒu)自主(zhǔ)研發多種容積(jī)泵和(hé)離心(xīn)泵的能力,并與(yǔ)蘭州理工(gōng)大學流體工(gōng)程與控制學(xué)院、中國農業大學流(liú)體機(jī)械學院、浙江工(gōng)業大學(xué)工業泵(bèng)研究所(suǒ)、東華大(dà)學機(jī)械工程學(xué)院、西安交大能源動(dòng)力學院、北(běi)京化工大學建(jiàn)立了戰(zhàn)略性技(jì)術合(hé)作關系。

經典研(yán)發案例(lì):海軍艦(jiàn)船專用五(wǔ)螺杆泵,大流量雙螺杆泵(bèng),油田(tián)油氣(qì)沙水混(hùn)輸(shū)專用(yòng)雙螺杆泵,具有(yǒu)專利技術(shù)的高壓注(zhù)水泵,具有(yǒu)國際先進(jìn)技術(shù)的高(gāo)粘度流體(tǐ)輸送泵,具(jù)有國際先進水平的(de)圓弧齒輪泵。

2、生(shēng)産裝(zhuāng)備的(de)優勢

公司堅(jiān)持(chí)着眼長遠和未(wèi)來,着(zhe)眼基(jī)礎(chǔ)裝(zhuāng)備建(jiàn)設,緻力(lì)于科研(yán)、生産和檢測能(néng)力的提(tí)高,緻力(lì)于科研(yán)、生産和(hé)檢測技術(shù)的提(tí)升,共有各(gè)種科(kē)研生産(chǎn)設備320台(tái)套,其中:各(gè)型加工中心38台套,各型數控機(jī)床22台(tái)套,各型精(jīng)大稀(xī)機床設備12台套(tào),各型專用普通機床(chuáng)設備35台套(tào)裝;共(gòng)有專用檢(jiǎn)測設備26台套,并(bìng)建有三座标專(zhuān)用檢測室,精密(mì)測試室,機械強(qiáng)度檢測室,理化(huà)試驗室;并建有(yǒu)符合國(guó)家b級标(biāo)準的(de)容積(jī)泵、離心泵綜合(hé)試驗(yàn)站,試(shì)驗站可以(yǐ)滿足公司各種産品性(xìng)能檢(jiǎn)測(cè)需要,可以滿足(zú)國家和(hé)客戶各種檢(jiǎn)測要求。

丁苯乳(rǔ)膠輸送泵用nyp110-ru-t1-w11,保溫轉(zhuǎn)子泵(bèng)配減速機,裝(zhuāng)機(jī)械密(mì)封填料密封